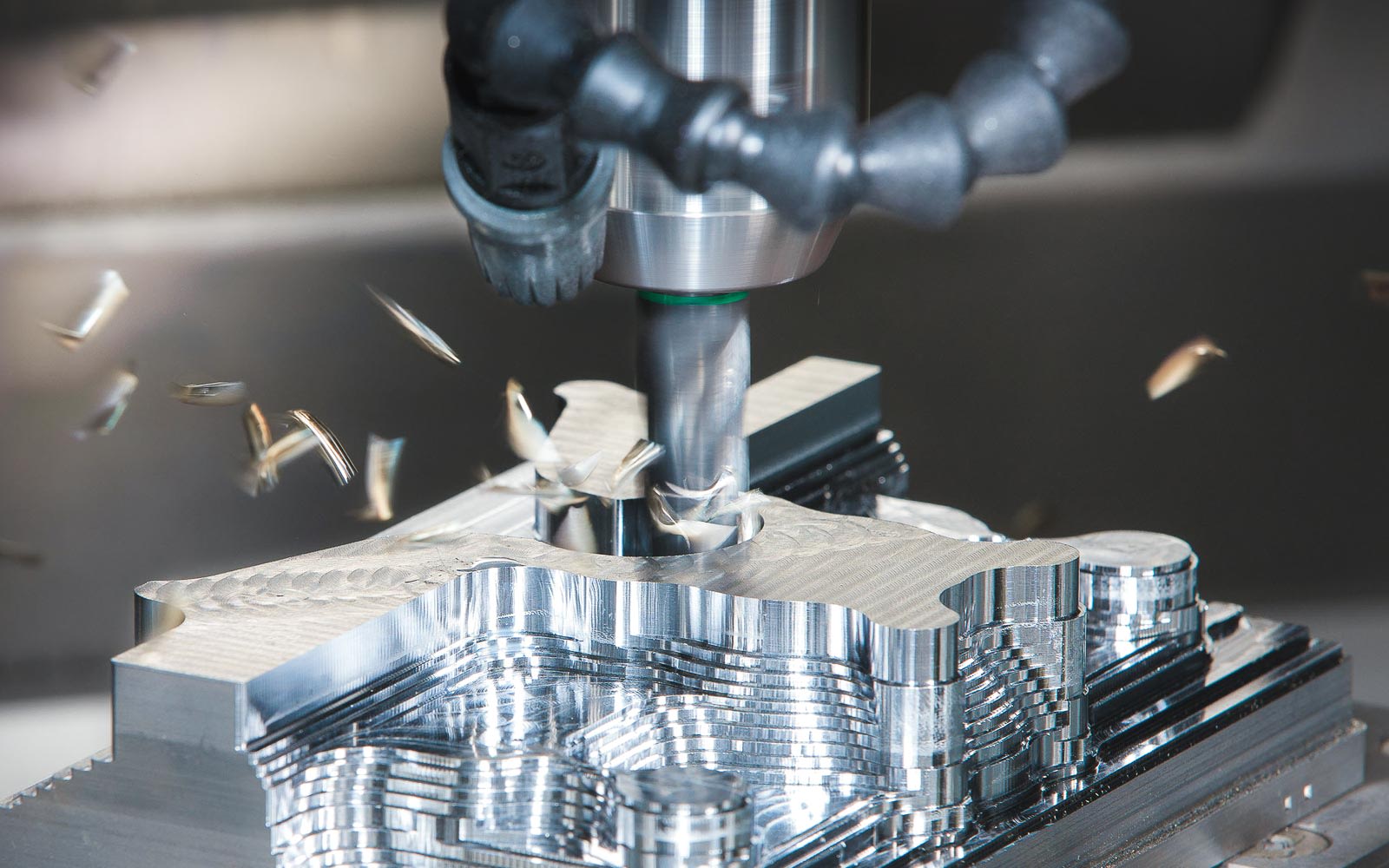

CNC machining is a process of making products from a variety of materials using computer-controlled machines. This process can be used to manufacture products with a high degree of accuracy and precision. CNC machining is used in a variety of industries, including aerospace, automotive, and medical. That being said, one of the challenges CNC machine shops face is the time it takes to set up the machine and program each new job. This can be a major bottleneck in the manufacturing process. However, speeding up the CNC machining process is critical to producing more parts in less time. This is important because it helps shorten product delivery times and enables companies to respond quickly to customer needs. In addition, faster production speeds help reduce overall production costs. CNC machining companies can implement to speed up the CNC machining process to increase efficiency and productivity.

An Effective Way to Improve CNC Machining Speed

One of the main advantages of CNC machining is that it is very fast. These machines can operate at high speeds and produce large quantities of objects in a short period of time. However, there are a few things you can do to further increase the speed of CNC machining. Implement the following to help increase CNC machining speed.

Choose the right machining plan:

With so many different machining plans, it can be difficult to know which one is right for your business. When choosing a machining plan, you need to consider several factors. First, you need to consider the size and complexity of the part you are machining. If you are machining large or complex parts, you will need a more robust machining plan. Second, you need to consider the tolerances that need to be met. The tighter the tolerances, the more precise the machining plan needs to be. Finally, think about what you need to achieve. Consider all of these factors and others, and create a machining plan.

Simultaneous machining operations:

Performing simultaneous machining operations can help speed up your CNC machining process. By running multiple operations simultaneously, you can reduce overall machining time and increase efficiency. However, doing so can be tricky and requires careful planning and coordination. But with proper preparation, you can successfully perform simultaneous machining operations and improve your CNC machining process.

There is an organized floor management system:

Having an organized shop floor management system can help speed up the machining process. An organized shop floor management system will help you keep track of your workpieces and tools, as well as their machining sequence. This will allow you to quickly and easily set up your CNC machine for each job, and it will also help you avoid mistakes that can slow down the process. With a little planning and thought, you can make the process easier and faster, and you can avoid costly mistakes that can hinder production.

Regularly train your staff and mechanics:

CNC machining is a complex process that requires skilled operators. To ensure your machining process runs fast, smoothly and efficiently, it is important to train your staff and operators regularly. When your employees are properly trained, they will be able to operate machines faster and more efficiently, ultimately increasing productivity.

Planned Maintenance Schedule:

Regular maintenance is essential to keep your machine running smoothly and efficiently. Think of it this way: if your machines are well-maintained, they're less likely to break down or experience other issues that could slow down production. This means you can get your products to market faster and keep your customers happy. Regular maintenance of CNC machines can include anything from checking the machine for wear to replacing worn parts. By maintaining your machine regularly, you can extend its lifespan and keep it running at peak performance.

Additional Tips to Increase CNC Machining Speed

Use high-quality tools, tool holders and workholdings

Use the correct type of cutting fluid

Use the correct cutting speed

Use the correct type of lubricant

Set the correct machining parameters

Use the correct cutting strategy.

Reduce cycle time

Reduce setup time

Reduce tool changes

Improve process planning

In a world where time is money, it's important to work with a CNC shop that can produce parts quickly without sacrificing quality. If you want to get parts quickly and without any problems, you need to find a CNC shop that can provide both. Fortunately, there are a number of shops that offer high-quality CNC machined parts in a timely manner, such as BDE Manufacturing Technologies. By working with a store like BDE, you will be able to get your parts quickly without any issues.